Tablet Hardness Tester

Tablet hardness testers are primarily used in the pharmaceutical industry to measure the mechanical integrity and breaking point of tablets, ensuring they can withstand handling, packaging, and transportation without compromising quality or safety. They are crucial for quality control, regulatory compliance, and process optimisation during tablet manufacturing.

Key uses of tablet hardness testers include:

Determining breaking force: This is the core function, measuring the force required to fracture a tablet, which indicates its strength.

Ensuring quality control and consistency: Consistent hardness across batches is vital for reliable drug delivery and performance.

Assessing mechanical properties: They help understand how tablets behave under various stresses encountered during their lifecycle.

Evaluating formulation and process optimization: Data from hardness testers informs adjustments to tablet formulations and manufacturing parameters like compression force.

Meeting regulatory standards: Pharmaceutical manufacturers must comply with regulations (e.g., USP <1217>, Ph. Eur. 2.9.8) that often require hardness testing.

Ensuring durability and patient safety: Proper tablet hardness prevents breakage during handling and ensures the tablet remains intact for the patient.

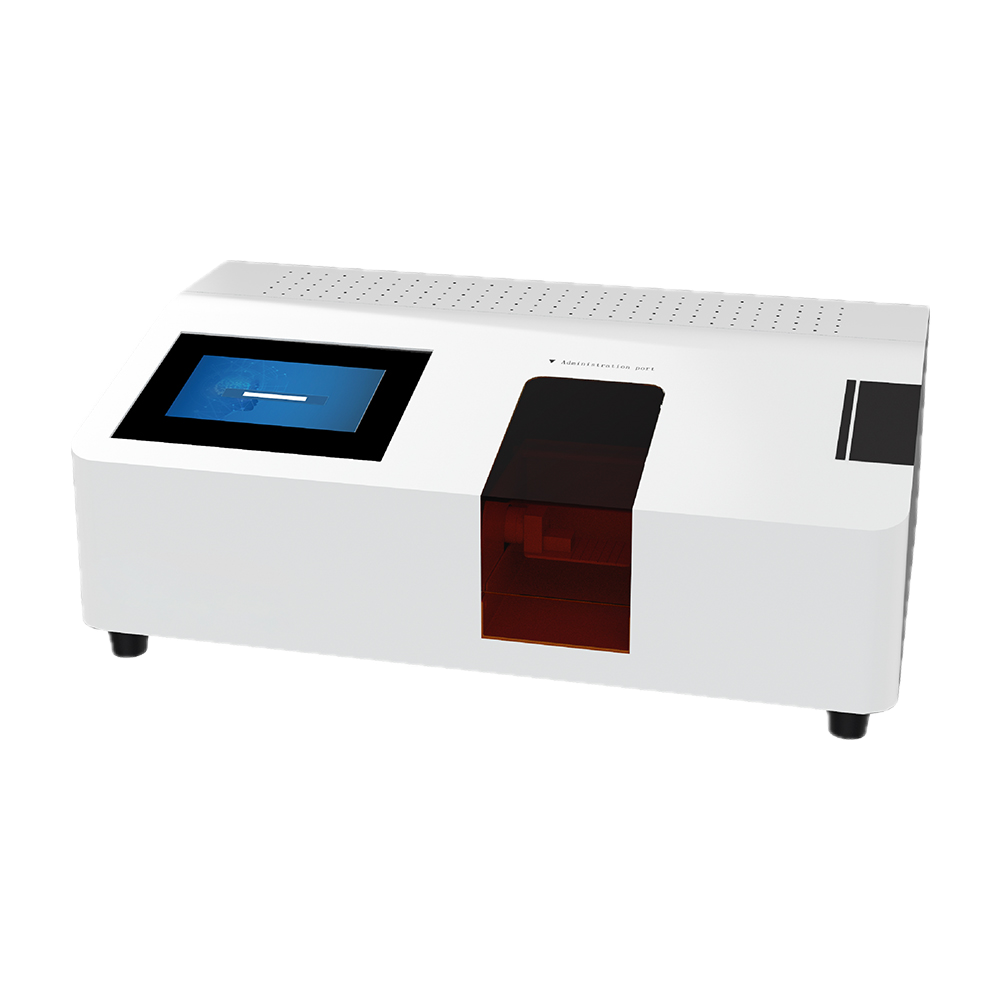

Drawell Tablet Hardness Testers, like the DW-THT-1350 model, are designed for comprehensive tablet analysis, featuring ranges for hardness (0-350N) and diameter (2.0-25.0mm) with resolutions of 0.1N and 0.01mm respectively, and supporting both manual and automatic continuous measurements up to 100 tablets. These instruments often include a 5-inch capacitive touch screen, real-time clock, alphanumeric data entry for sample identification, and multilingual support (Chinese/English options).

Key Specifications and Features of Drawell Tablet Hardness Testers:

Measuring Range: Typically includes a hardness range of 0-350N with a resolution of 0.1N, and a diameter range of 2.0-25.0mm with a resolution of 0.01mm. Some models, like the Infitek THDT-3, offer a hardness range of 2-200N (0.2KG-20KG) and a tablet diameter range of 2-40mm, with a resolution of 0.1N (0.01Kg).

Units of Measurement: Support for various units like N, Kg, Kap (optional), and mm/inch for diameter (optional).

Measuring Method: Can perform manual single-piece testing or automatic continuous measurement, with the ability to test up to 100 tablets in a continuous run on certain models.

Display and Interface: Many models feature a 5-inch capacitive touch screen for user interaction. Others may have a 7-inch high-resolution display or a 4-line x 40-character wide display.

Data Management and Reporting: Often include alphanumeric entries for sample names and identification/batch numbers, with options for date and time display via a built-in Real Time Clock (RTC). Reports can be printed and are often GLP (Good Laboratory Practice) compliant, especially with factory-entered customer names and serial numbers.

Some models also feature multilevel passing limits for detected values and calibration functions with reminders.

Additional Features: Some models incorporate features like 12-position carousels for automatic tablet transfer, simultaneous measurement of thickness, length/diameter, and hardness, and built-in sweeper blades for debris removal. They may also include non-volatile memory for storing methods and user results.

Power and Dimensions: Power supply is typically AC110/220V±10%, 50/60Hz. Dimensions and weight vary by model; for example, a THT-3 model measures 400240140mm and weighs 10kg

Tablet Hardness Tester DW-THT-1350

Tablet Hardness Tester