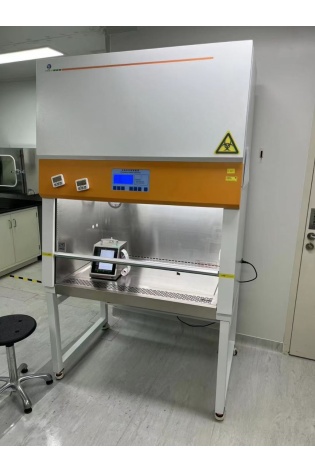

Vertical Laminar Flow Hood

Lead Time: 4-8 Weeks

Vertical Laminar Flow Hood

Vertical laminar flow hoods create a sterile, downward airflow (filtered by HEPA) to protect sensitive products from airborne contaminants, making them ideal for microbiology, pharmaceutical compounding, electronics assembly, and food testing, especially for bulky items or powders where top-down flow prevents material blow-back and offers operator safety. Vertical Laminar Flow Hood

Key Uses & Applications:

Microbiology & Cell Culture: Protecting cultures (bacteria, cells) from dust and microbes during preparation and growth.

Pharmaceuticals: Ensuring sterility for drug compounding, formulation, and quality control.

Electronics Manufacturing: Preventing particle contamination during assembly of sensitive components.

Medical & Dental Labs: Sterile handling of devices, materials, and diagnostic samples.

Food Industry: Handling samples in clean conditions for testing and quality assurance.

Research: Proteomics, mycology, and other research requiring particle-free environments.

Why Vertical Flow is Preferred for Certain Tasks:

Operator Safety: Air flows downwards, away from the user, protecting the operator from aerosols and powders.

Large Equipment: Accommodates tall or bulky equipment better than horizontal hoods.

Powder Handling: The downward flow prevents powders from being blown into the operator’s face.

Less Turbulence: Reduces air disturbance, creating a more stable clean zone.

How it Works:

Air is drawn in from above the workspace.

It passes through a pre-filter and a high-efficiency HEPA filter.

Filtered air flows vertically downwards in a single, uniform (laminar) stream.

This continuous downward sweep carries contaminants away from the work surface, exiting the front opening.

Laminar Flows are part of laboratory clean benches.

Characteristics:

1. Vertical laminar flow, with SUS 304 stainless steel bench board, effectively prevents external air into the cleaning work environment.

2. High quality low noise centrifugal fan ensures the stable speed. Touch type air flow control system, the five sections wind speed control, adjustable speed 0.2-0.6m/s (initial:0.6m/s; final:0.2m/s)

3. High quality filter ensures dust can be filtered more than 0.3um.

4. UV lamps and lighting control independently.

Optional separating laminar flow cabinet

| Model | CJ-1S | ||||

|

Applicable Station |

one operator&two sides | ||||

| Airflow Direction | Vertical | ||||

| Function | Cleanliness | Class 100 | |||

| Collection Efficiency | ≥99.9% of 0.5um particle | ||||

| Colony Count | ≤0.5/vessel (petri dish is φ90mm ) | ||||

| Wind Speed | initial:0.6(m/s),final:0.2 (m/s) | ||||

| Wind Speed Range | 0.2-0.6 (m/s) | ||||

| Noise Level | ≤62db | ||||

| Vibration Semi-Peak Value | ≤3um | ||||

| Illumination Intensity (Lx) | ≥300LX(Activity Center) | ||||

| Work Surface Bearing | 50kg | ||||

| Composition | Inner Chamber | Stainless steel plate | |||

| Outer Shell | Cold rolling steel electrostatic spraying exterior | ||||

| Operation door | Tempered Glass | ||||

| HEPA Filter (mm) | 820*600*50 one piece | ||||

| Pre-Filter (mm) | 520*490*5 one piece | ||||

| Fluorescent Lamp | 20W*1 | ||||

| UV Lamp | 20W*1 | ||||

| Top Fan | 300W one piece | ||||

| Controller | Display | LED | |||

| Wind Speed Control | Intelligent multi-level adjustable | ||||

| Additional Function | The bottom horizontal adjustment, one key to open and close lighting sterilization | ||||

| Specification | Inner Size (W*L*H)(mm) | 780*670*550 | |||

| Exterior Size (W*L*H)(mm) | 935*725*1690 | ||||

| Packing Size (W*L*H)(mm) | 1100*900*1385 | ||||

| Max Power | 0.4kW | ||||

| Current Rating (50/60Hz) | AC220V/1.8A | ||||

| NW/GW kg | 160/225 | ||||

Vertical Laminar Flow Hood