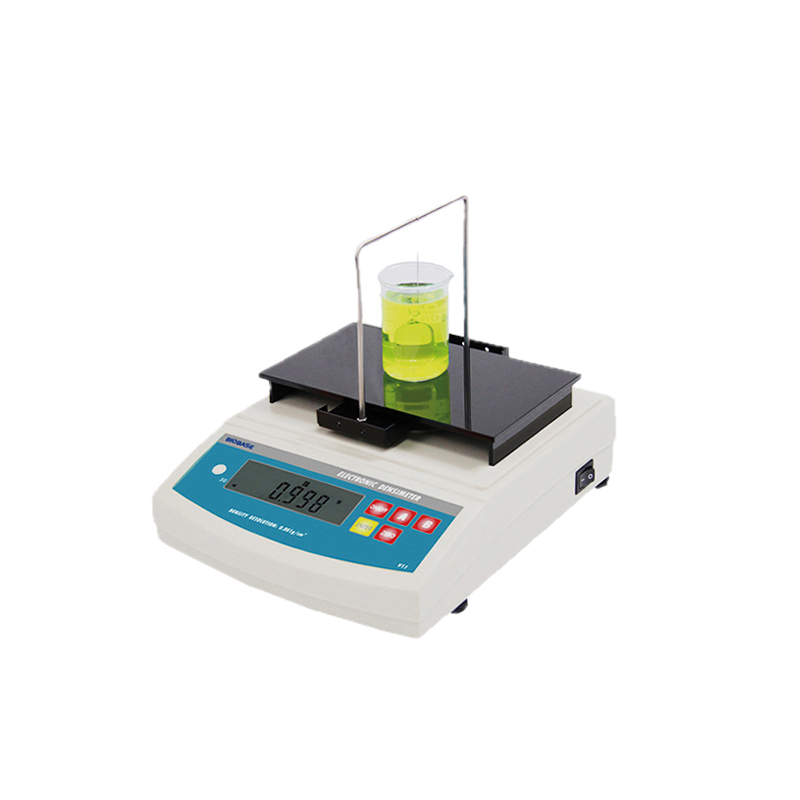

Liquid Density Meter

Benchtop Liquid Density Meter for Any Type of Liquid

A liquid density meter is used to continuously measure the density or concentration of liquids and liquid mixtures.

These meters are employed across various industries for process control, product identification, and quality assurance.

rheonics SRD » Density Meter inline online specific gravity …

Here’s a breakdown of Liquid Density Meter uses:

1. Process Control:

Blending:

Density meters ensure accurate mixing ratios in various processes, like blending fuel or chemicals.

Product Change Detection:

They can identify when one product is replaced by another in a pipeline, crucial in multi-product pipelines.

Interface Detection:

They help pinpoint the interface between different liquids in a pipeline, preventing contamination.

Quality Control:

Density measurement is used to monitor and maintain the quality of products throughout the manufacturing process.

Concentration Measurement:

They determine the concentration of substances in a solution, such as sugar in beverages or alcohol in beer.

2. Product Identification:

Density meters can be used to identify different liquids based on their unique density values, aiding in product verification and quality control.

3. Specific Applications:

Oil and Gas:

Density meters are essential in oil and gas industries for custody transfer, blending, and process monitoring.

Chemical and Petrochemical:

They play a crucial role in chemical and petrochemical processes for monitoring reactions, product consistency, and quality control.

Food and Beverage:

Density measurement is used in the food and beverage industry for controlling sugar content in drinks, alcohol levels in beer and wine, and the quality of various food products.

Pharmaceuticals:

They are used in pharmaceutical manufacturing for precise control of drug formulations and quality control.

Mining and Wastewater:

Density meters are used to measure the density of slurries and sludges in mining and wastewater treatment processes.

Other Industries:

Density meters find applications in various other industries such as paper, pulp, and semiconductor manufacturing.

Features

1. No damage testing, cleaning and environmental protection.

2. Unable to measure sample which is hollow or with inserted gems.

3. Multi-mode, gold mode, platinum mode, other precious metals mode can be switched.

4. Could be used as precision balance.

5. Top and bottom limitation of K value, purity and density of gold. And prompt alarm.

6. Automatic zero tracking, buzzer warning, and overload warning.

7. Water and other liquids could be used as measurement medium.

8. RS-232C is included.

Product Paramenters

Model. BK-DME300S. BK-DME600S

Capacity. 0.005-~300g 0.005~600g

Density Resolution0.001 g/cm3

Density Range 0.001~99.999g/cm3

Measuring Time. About 5 s

Measuring Principle. Archimedes principle

Specific Gravity Measuring Frame. Unibody injection forming professional specific gravity measurement frame

Size: 176*105*111mm(L*W*H)

Measuring Tank Unibody injection forming transparent measuring tank

Size: 169*98*83mm(L*W*H)

Liquid Density Meter

Standard Accessories Tank, testing board, tweezer, thermometer,100G weight, windshield, a set of particle measuring assembly, a set of floating body

measuring assembly, power transformer.

Optional Accessories. DE-40 printer

Power Supply AC110/220V±10%, 50/60Hz

Package Size(W*D*H)mm. 450*200*360

Gross Weight(kg). 4.5

Liquid Density Meter