Lab High Pressure Homogeniser

12-25L/H 1500bar Laboratory High-Pressure Nano Homogenizer For Lab

A high-pressure homogenizer in a laboratory setting is primarily used for reducing particle size, creating nano-scale emulsions, and disrupting cells. These applications are crucial in various industries including pharmaceuticals, biotechnology, and food science.

Lab High Pressure Homogeniser

Specific Lab High Pressure Homogeniser Uses:

Particle Size Reduction:

High-pressure homogenizers can reduce the size of particles in a suspension, leading to more stable and uniform products.

Nanoemulsions:

These devices are essential for creating nanoemulsions, which are used in various applications like drug delivery and cosmetics.

Cell Disruption:

High-pressure homogenisers can efficiently disrupt cells, releasing intracellular components for further analysis or processing.

Liposome and Nanoparticle Preparation:

They are used in the production of liposomes and nanoparticles, which are important in drug delivery and other biomedical applications.

Deagglomeration:

High-pressure homogenization can break down particle agglomerates, improving the homogeneity and stability of suspensions.

Other Applications:

They are also used in the food industry for homogenization of dairy products and beverages, and in the chemical industry for various applications like nanomaterial synthesis and coating production.

Key Features:

High-Pressure Operation:

These homogenizers operate at high pressures (often up to 2000 bar or even higher) to achieve the desired effects on particle size and cell disruption.

Interaction Chambers:

Many high-pressure homogenizers utilize interaction chambers, where the sample is forced through narrow channels, resulting in high shear and impact forces that lead to particle size reduction.

Cooling Systems:

Some high-pressure homogenizers are equipped with cooling systems to manage the temperature increase that can occur during high-pressure homogenization, which can be important for heat-sensitive samples.

Precision and Control:

Modern high-pressure homogenizers offer precise control over parameters like pressure and flow rate, allowing for optimization of the homogenization process.

Lab High Pressure Homogeniser

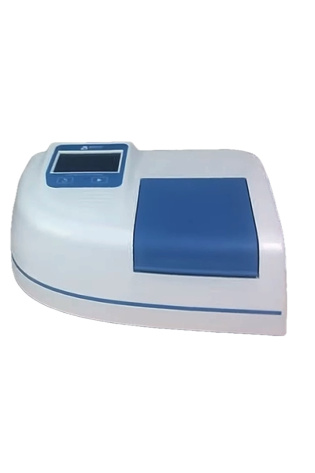

DW-150A(-PS) High Pressure Homogenizer is a miniaturized desktop biological sample processing device. The instrument has a built-in cooling circulation system to directly cool the homogenizing head, and homogenizing valves for different applications can be purchased. It has the characteristics of high pressure, small volume, convenient operation, high processing efficiency and large sample output. It is a standard equipment for R&D and production in bioengineering and biopharmaceutical industries.

Lab High Pressure Homogeniser Performance characteristics:

* Invention patent: structure design of built-in cooler

* High level of hygiene: 316L stainless steel material that meets food and drug requirements is used

* Multi-function options: optional secondary homogenization module, and optional homogenization valve for different applications

* Temperature controllable: The inlet and outlet of the cooling joint are connected with the constant temperature bath, effectively controlling the temperature rise of the homogeneous material

* Pressure can be adjusted: design homogeneous pressure 0~1200Mpa can be adjusted arbitrarily

* High crushing efficiency: the particle size of the material can be uniformly refined to below 100nm, and the crushing rate is greater than 95%

Instrument parameters

1. Model: DW-150A

2. Motor power: 3.0KW class 8

3. Maximum flow: 12-25 liters/hour

4. Maximum working pressure: 1500bar

5. Maximum product viscosity: 2000cP

6. Material maximum feed particle diameter: <500 microns

7. Maximum product temperature: 90℃

8. Maximum steam temperature: 121℃

9. Dimensions: L840*W620*H540mm

10. Built-in cooling: Optional low temperature thermostat, can control the sample at 5 ~ 20 ℃

Lab High Pressure Homogeniser