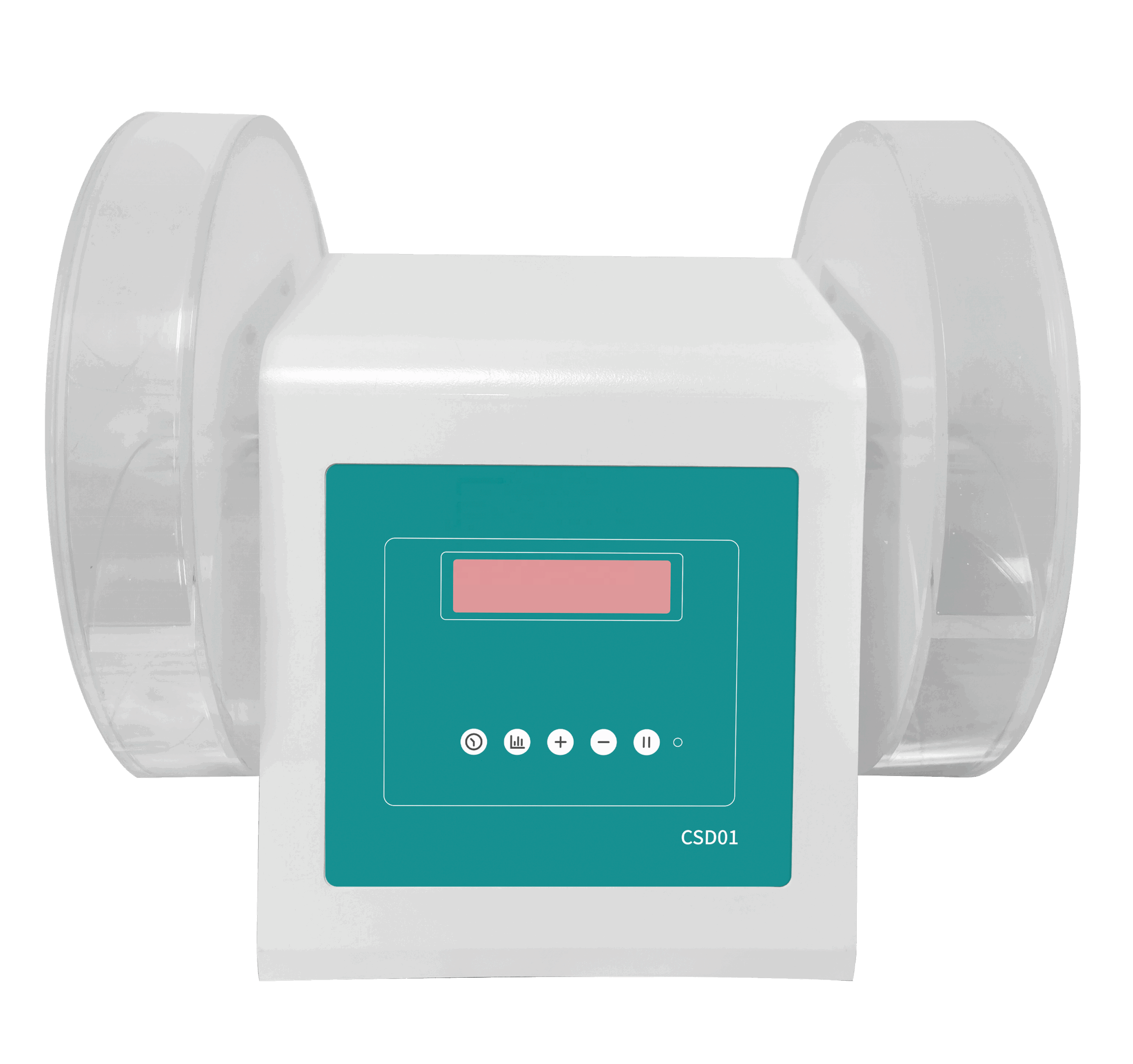

Friability Tester

A friabilometer is used to test the physical strength and durability of materials like pharmaceutical tablets and malt grains. It is primarily used in two main fields: the pharmaceutical industry to ensure tablets can withstand shipping and handling by measuring their tendency to chip or break, and the malting industry to monitor the quality and modification of malt after drying.

-

Quality control:

Tests the mechanical strength and abrasion resistance of non-coated tablets.

-

Durability assessment:

Determines how well a tablet can withstand forces like vibration, rubbing, and impact during manufacturing, packaging, and shipping.

-

Chip and breakage analysis:

Evaluates the tendency of tablets to chip or powder by subjecting them to mechanical stress in a rotating drum and measuring the resulting mass loss.

-

Malt quality monitoring:

Assesses the brewing quality of malt immediately after drying.

-

Modification assessment:

Measures the “friability” or how easily the grain can be crushed, which indicates the extent of modification during the malting process.

-

Process control:

Helps malthouses detect and correct irregularities in the malting process by providing immediate feedback on malt quality.

-

Consistency control:

Allows breweries to check the quality of malt upon delivery and adjust mixtures to ensure consistency.

|

Model

|

DW-CSD01

|

|

Speed

|

25±1 rpm

|

|

Time setting

|

4 minutes, resolution: 1 second

|

|

Lap setting

|

100 revolutions, display resolution is 1 revolution

|

|

Timing range

|

0-9:59:00

|

|

Counting range

|

0-99999 times

|

|

Power

|

20W

|

|

Turntable size

|

Inner diameter 286mm, depth 39mm

|

Friability Tester